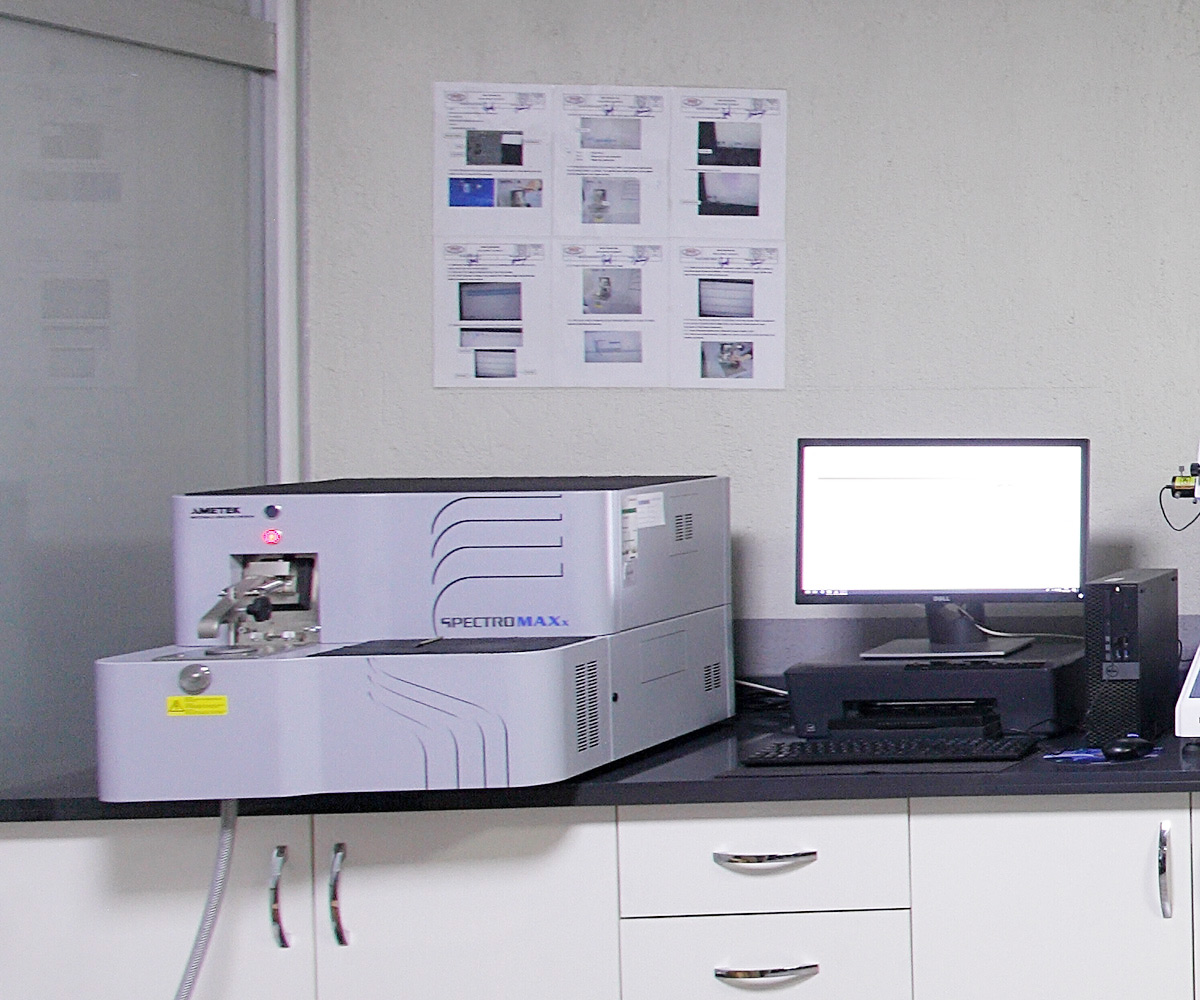

Speed Metal Otomotiv acknowledges and cares about the importance of the controls of incoming materials. One of the verification steps of procured raw materials is optical emission spectral analysis carried out by the help of spectrometer device. Our company is able to detect the variety and proportion of elements in raw materials and compares them with the values mentioned in the norms, eventually helping validate raw material type.

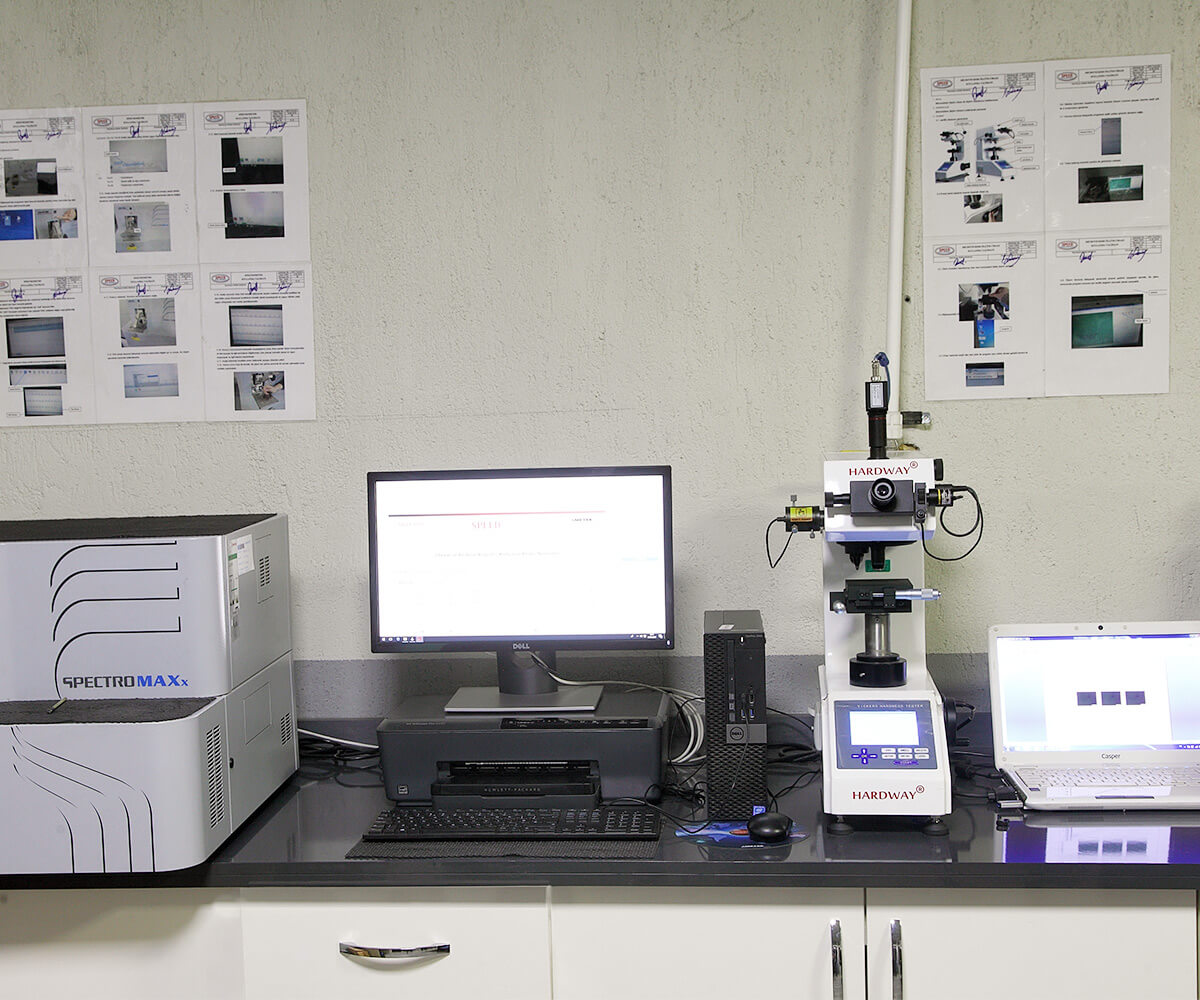

Our company uses Rockwell hardness tester device while measuring hardness values of parts and raw materials, also parts going under tempering or induction. Hardness values provided are in HRB, HRC and Brinell.

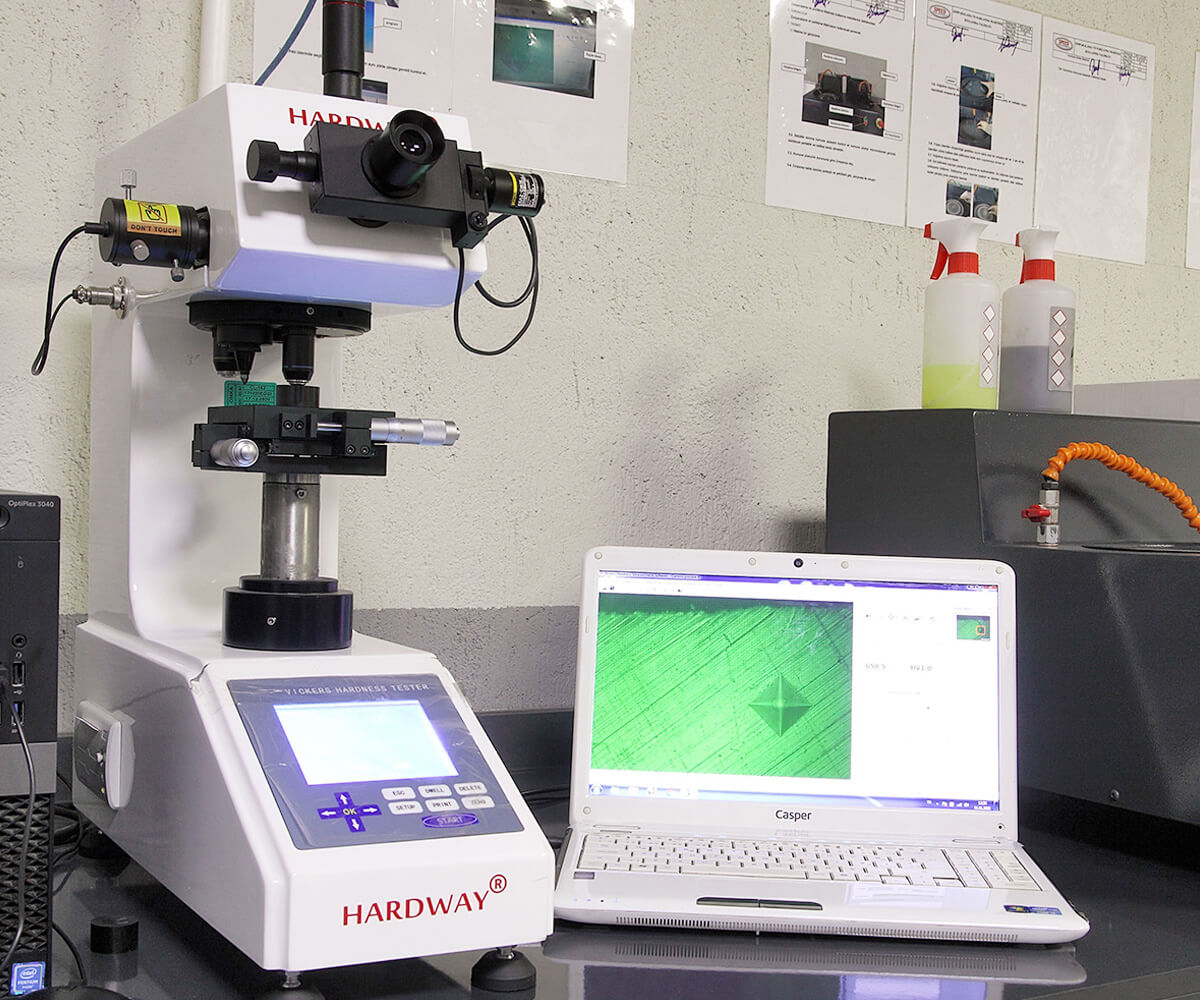

Micro Vickers hardness tester is used to measure the hardness on inserts, pressure cups and steel inserts which are meant to have hard surfaces by carbonitriding. Thanks to the microscope and software on the device, depth of hardness analysis can be done and parts are validated against requirements.

Surface roughness on contact areas is important for parts like inserts, pressure cups and steel inserts, and it is measured by the help of this device.

Parts with zinc plating, phosphating, cataphoresis, static paint, zinc nickel and zinc flake coatings are evaluated in terms of coating thickness after they are delivered to our company and they are validated against the requirements.